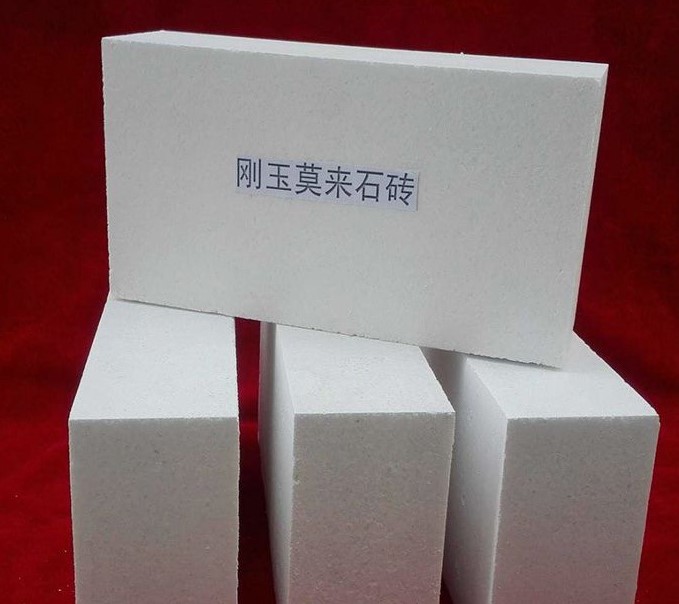

Zircon Corundum Mullite Brick

Zircon Corundum Mullite Brick Introduction

Zircon corundom mullite bricks uses high grade mullite grog and australia imported zircon sand as raw material. Melted raw material in electric furnace under high temperature and cast the liquid into mould.

Zircon Corundum Mullite Brick Features

1.Excellent wear resistance

2.Low thermal expansion

3.High true density

Zircon Corundum Mullite Brick Physical and Chemical Index

Chemical composition(%) | SiO2 | Al2O3 | Na2O | ZrO2 | Others |

CMZ-5 | 19 | 73 | 1.0 | 5.5 | 1.5 |

Physical Properties |

True Density(g/cm3) | Cold Crush Strength (Mpa) | Thermal Expansion(%) 1150℃ | Thermal Conductivity(500-1500℃) | Porosity(%) | Bulk Density(g/cm3) |

3.54 | >350 | 0.8 | 4.6w/m.0k | <8 | 2.9-3.2 |

Crystalline Phase (%) |

Corundum | Mullite | Glass Phase | Brazilite |

38 | 40 | 17 | 5 |

Zircon Corundum Mullite Brick Application

It is mainly used in areas that require high abrasion and temperature resistance, such as gliding rail bricks in steel pusher metallurgical furnaces, the tapping platform (tapping spout) for tapping platform style walking beam furnaces ans also as the interior for destructors.

English

English

русский

русский

中文

中文